Latest Products

-

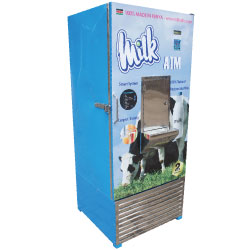

Milk Atm

KSH185,000

Milk Atm

KSH185,000 -

Cooking Oil Atm

KSH99,900

Cooking Oil Atm

KSH99,900 -

Batch Pasteurizer

KSH185,000

Batch Pasteurizer

KSH185,000 -

Milk Cooling Tank

KSH185,000

Milk Cooling Tank

KSH185,000

All Liquids Packaging Machine - Water, Juice, Liquid food, Liquid Chemicals & More

Discover the filling solution for your liquid type

Filling PET Bottles Precisely & Safely For All Beverages

Choosing the right filling technology is essential to producing a consistently high quality beverage. We can help you choose the best filling technology for you, taking into account:

Hygienic requirements

Utilities consumption

Lowest total cost of ownership (TCO)

Skill levels of operators

Ambient production conditions

Transportation

JUICES, TEAS AND SPORTS DRINKS

IMPROVE QUALITY AND FLAVOUR WHILE PRESERVING FRESHNESS

No matter your beverage type, you need to protect from microbial contamination, keeping beverages bacteria-free without preservatives or additives. Whether it is still, high or low acid beverages, or those with or without pulps or particles, Our expertise in PET helps you achieve more.

From standalone equipment or complete line solutions, we can work closely with you to provide solutions for aseptic or hot filling that make storage more convenient and eliminate the need for a cold chain. This ensures that you can bring any beverage safely to market without preservatives and with a longer shelf-life - all while preserving quality, taste and freshness.

Explore our beverage packaging solutions that expand possibilities for liquid food packaging in PET

A wide range of technologies enables us to meet the individual needs of your business, matching your requirements for product quality, output and costs. Our full range of fillers offers:

-

-

1. Low TCO 2. Minimal maintenance 3. Strong performance 4. Complete product quality 5. Flexibility 6. Food safety

Your beverage deserves the best

DASE quality filling is determined by:

| 1. | Gentle beverage handling during the filling process, giving a precisely filled product |

||||||||||||||||||||||||||||||||||||||||||||||||

| 2. | Hygienic design of all parts that come in contact with the beverage | ||||||||||||||||||||||||||||||||||||||||||||||||

| 3. | Safe bottle-handling, which avoids stress without compromising filling. During the filling process,bottles stand -without moving | ||||||||||||||||||||||||||||||||||||||||||||||||

| under the filling valves in a fixed position, meaning: | |||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| 4. | Complete product quality | ||||||||||||||||||||||||||||||||||||||||||||||||

| 5. | Flexibility | ||||||||||||||||||||||||||||||||||||||||||||||||

| 6. | Food safety |

- Manufacturer: Dennis Art Science & Engineering